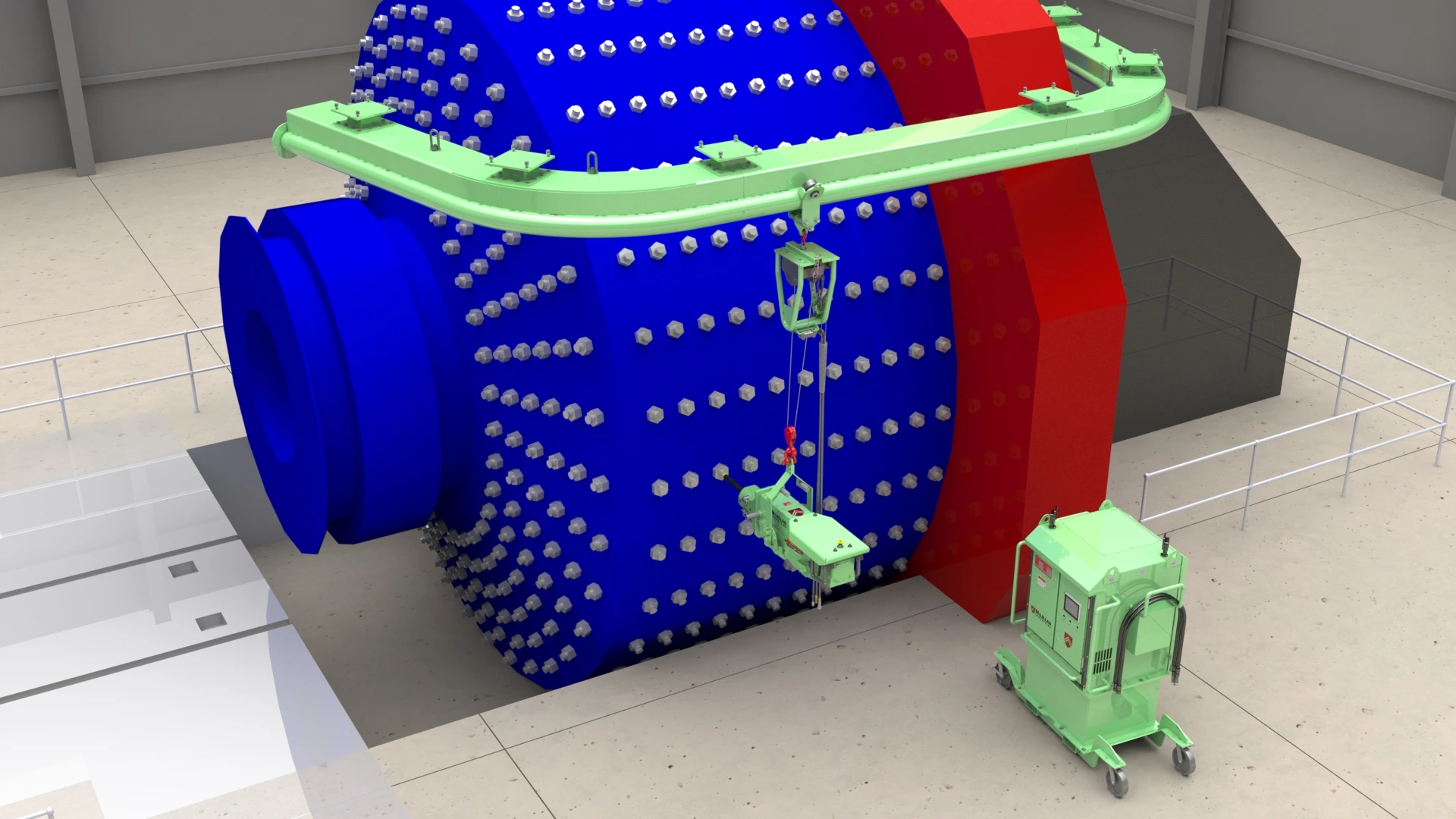

Mill Relining Equipment

McLellan Industries is the original designer of the Mill Liner Handler. Our experience and support are well known throughout the world.

With over 60 years of research and development experience, we custom-engineer and

manufacture quality-built equipment for servicing Ball, SAG, AG, and Rod type mills. This

maintenance equipment is essential for scheduled or emergency relines.

Our McLellan Mill Relining Equipment significantly reduces mill downtime while providing a maximum level of safety. Our equipment empowers your crew with a mechanized delivery of mill liners for easy transport and placement inside your mill. Let us help you with all aspects of the mill lining process. We can provide you with a custom reline service package designed to meet your needs.

Mill Maintenance Equipment & Service

-

- Mill Liner Handlers

- Rod Chargers

- Feed Chute Transporters

- Bolt Busters, with Hydraulic Power Units

- Jib Cranes for Bolt Buster Suspension

- Monorail Systems for Bolt Buster Suspension

- Ancillary Support Tools & Spare Parts

- Major / Minor Rebuilds & Service, Mill Relining Support

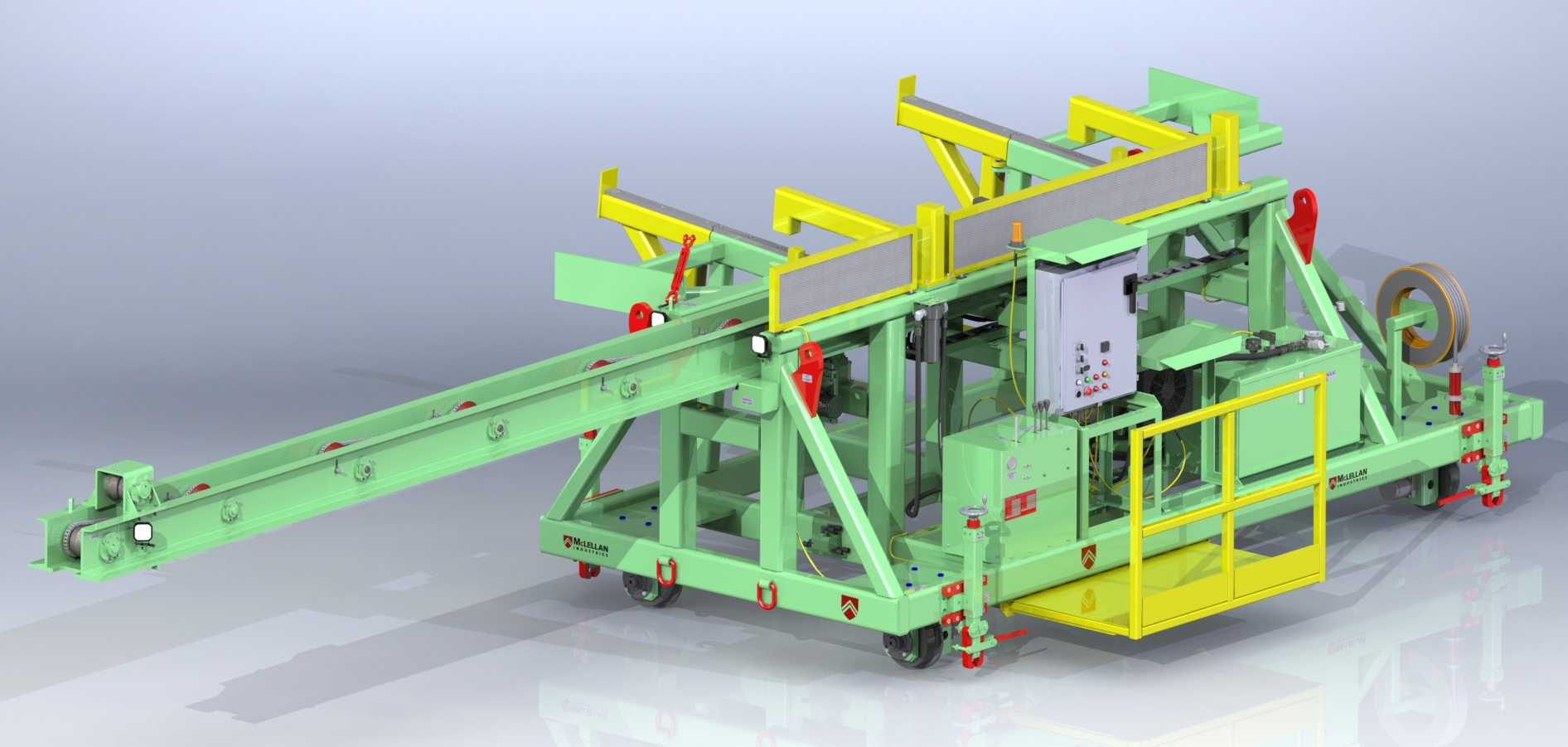

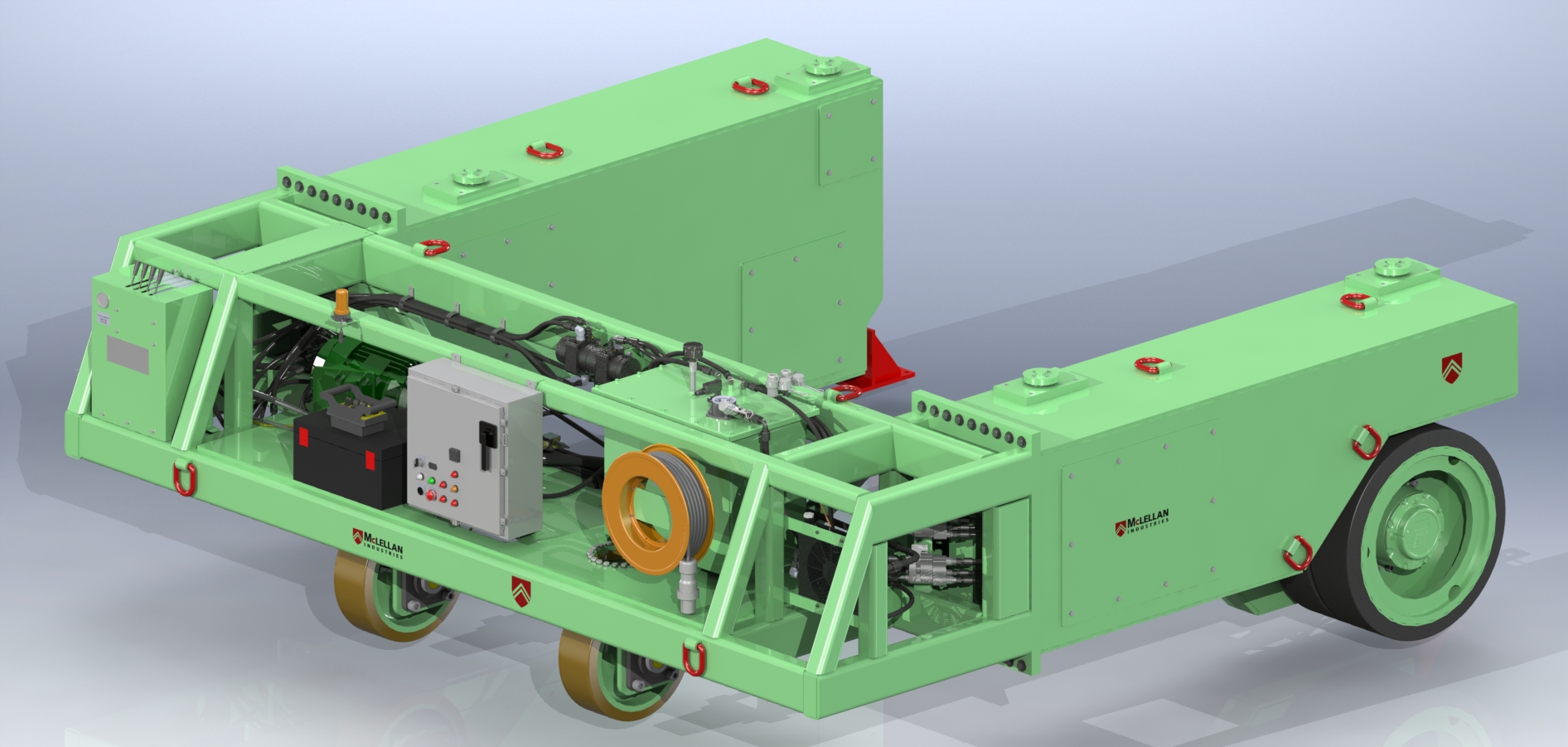

Mill Liner Handlers

Reliable, durable, and dependable construction allows for reliable service during critical, costly downtime. McLellan designed Mill Liner Handlers are designed to be user friendly.

It is made up of 7 major assemblies which includes Crane, Chassis, Main beam, Dolly cart, Turret, Manipulator with clamp.

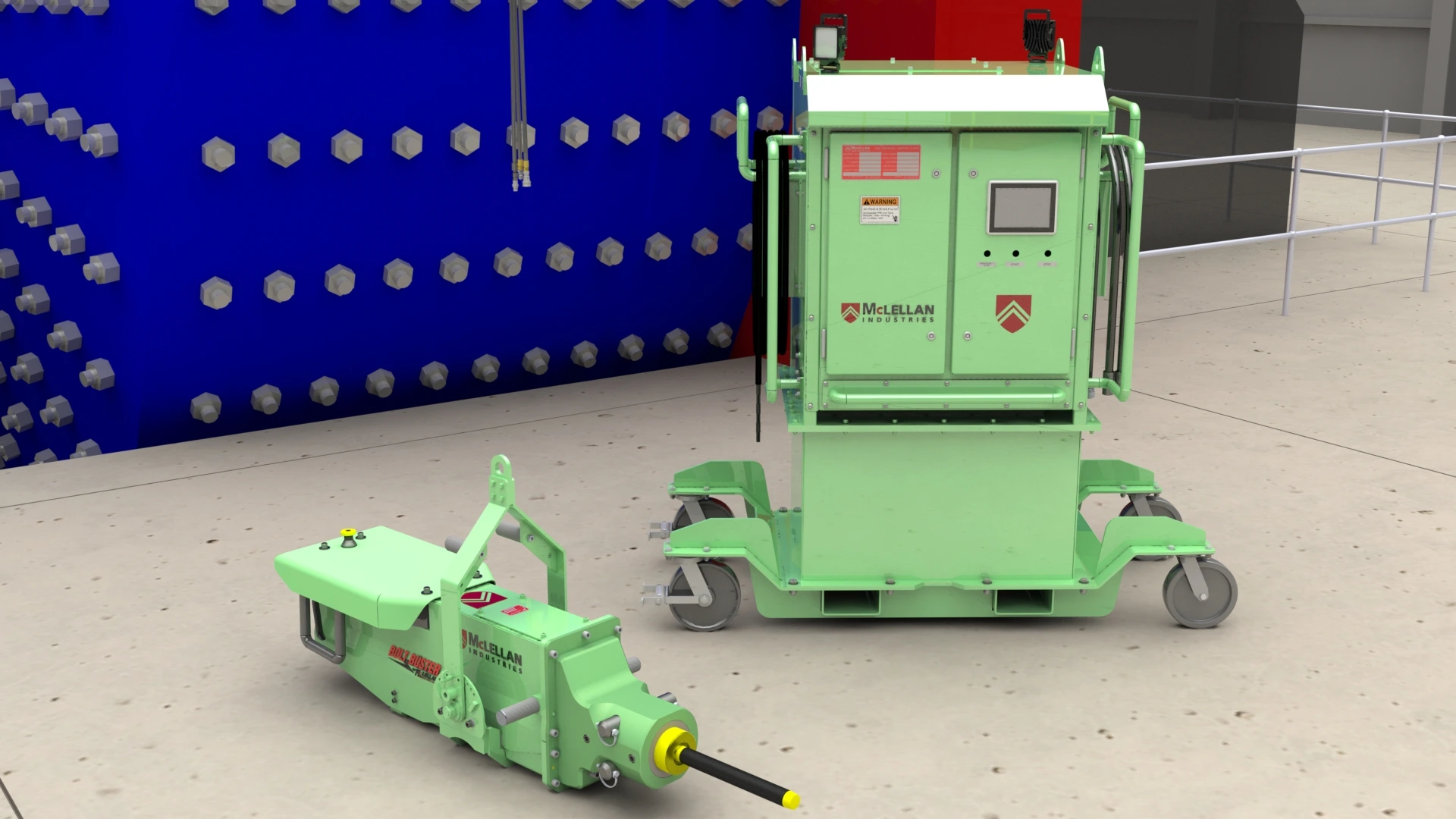

Rod Chargers

Reduce rod replacing time in your rod mill with an automated solution. Our Rod Charger is designed to propel rods into mills via an extendable boom. The McLellan Rod Charger reduces time and labor during critical relining & maintenance periods. The Rod Charger is designed to be the backbone of your mill rod replenishment process.

Feed Chute Transporters

Hasten the mill relining process by safely and quickly removing a mill’s feed chute away from a mill, even when fully choked, with our powered Feed Chute Transporter. The space made available by our Feed Chute Transporter jump starts the mill relining process, returning you to full production with minimal downtime.

Bolt Busters, with Hydraulic Power Units

The Hydraulic Bolt Buster and Hydraulic Power Unit (HPU) will incorporate features such as:

- Recoilless Hydraulic Bolt Buster Hammer which produces 1500 Joules of impact energy.

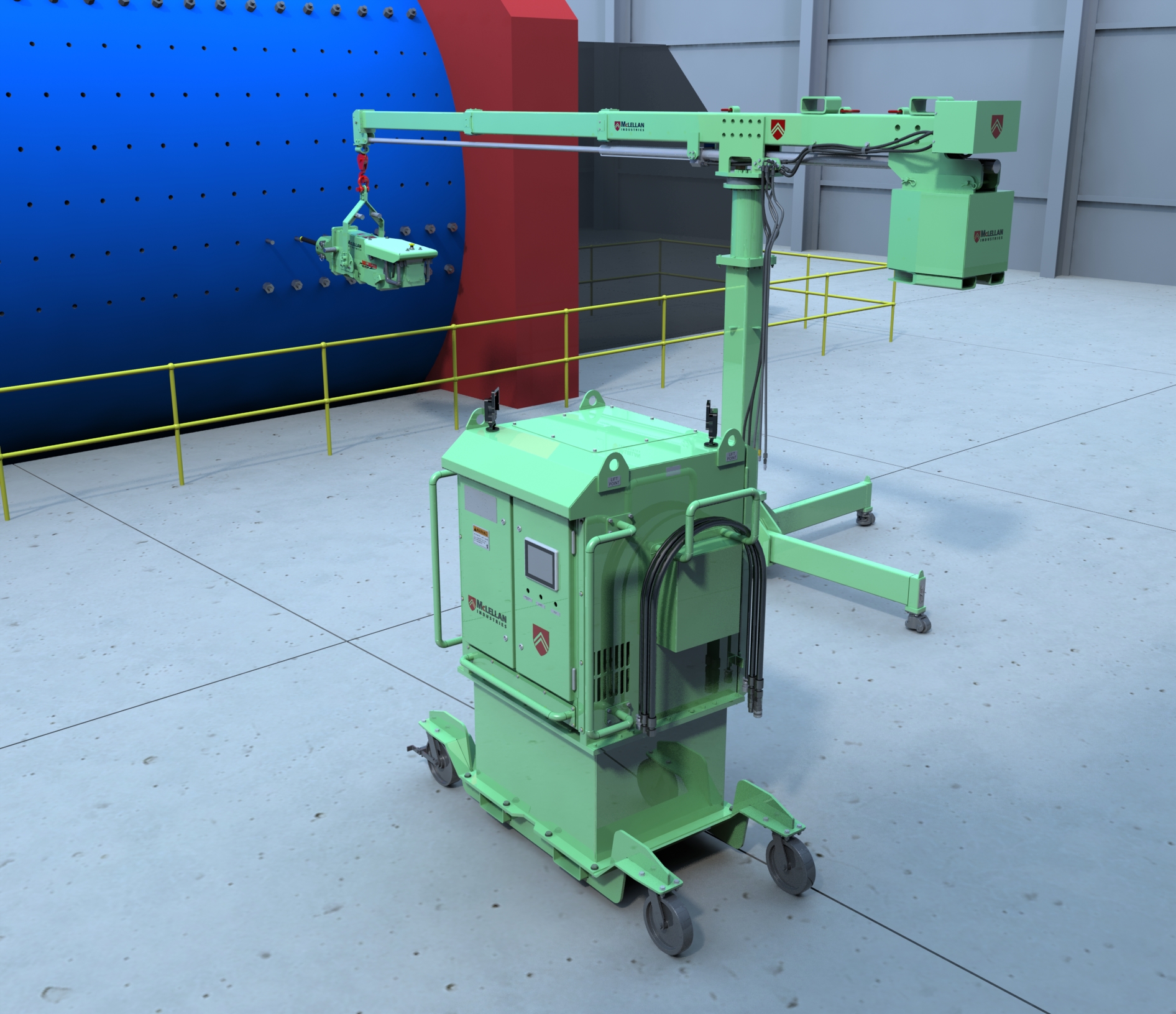

Jib Cranes for Bolt Buster Suspension

The Hydraulic Jib Crane will incorporate features such as:

- Bolt buster is suspended using a hydraulic jib crane rated to lift 1,200 Lbs. [545 Kgs].

Monorail Systems for Bolt Buster Suspension

The Monorail system will incorporate features such as:

- Monorail System consists of monorail tubes on one side of the grinding mill or on both sides based on mill requirements.

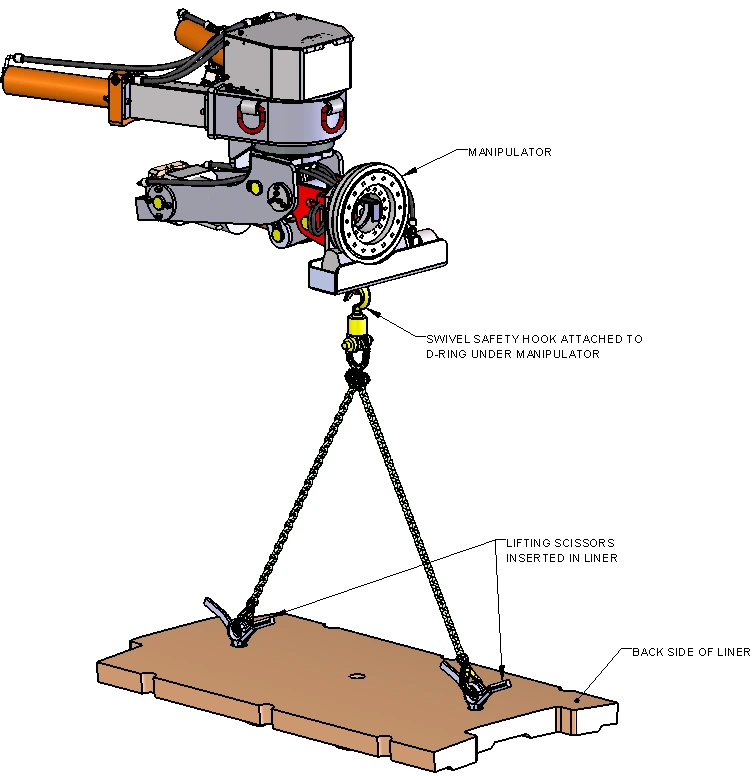

Ancillary Support Tools & Spare Parts

McLellan Industries designs and provides ancillary support tools required for relining which includes liner lifting scissors, liner lifting chain slings, fixtures for pulp liners. Designed as per the liner weight and bolt hole profile.

Major / Minor Rebuilds & Service, Mill Relining Support

We have upgraded many older mill liner handlers with new technology to maximize the productivity of the mill relining process.