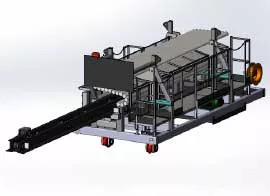

Rod Charger

Reduce rod mill rod replacing time with an automated solution. Capable of laying or propelling rods into mills via an extendable boom, the McLellan rod charger reduces time and labor during critical relining & maintenance periods. The Rod Charger has been designed to be the backbone for the Periodic Maintenance of the Mill Rod Replenishment. Each unit is designed to place rods through minimal mill openings. McLellan offers a customizable solution to rod charging designed by out in house team of engineers. Options include independently driven wheels or rails, rod racks for increased rod capacity, retracting beams, etc.

Reduce downtime by mechanically driving mill liners into place for easy bolt on action.

Reduce downtime by mechanically driving mill liners into place for easy bolt on action.

Reduce downtime by mechanically driving mill liners into place for easy bolt on action.

Features

- Main frame Computer designed structure that can be lifted into position by an overhead crane, and then anchored in front of the mill in need of rod replenishment. The structure is the main support for main beam, hydraulic and electrical systems, and the rods that will be placed in the mill.

- Rod rack Temporary holding area for the rods. This space is designed with the customer’s facilities in mind. Each rack is designed around a loading cycle time which ensures a constant feed into the mill, thus reducing downtime during critical maintenance periods.

- Main beam The structure that positions inside the mill for proper placement of rods. The main beam receives rods from the rod rack via loading actuators. Retractable for compact storage.

- Rod feeder A series of rollers mounted within the main beam that pushes the rods into the mill.

Options

- Halogen work lights

- Additional safety railings

- Remote controls and remote shut-off

- Rail wheels to serve multiple mills

- Custom paint job to match facility standards