Bolt Removal System

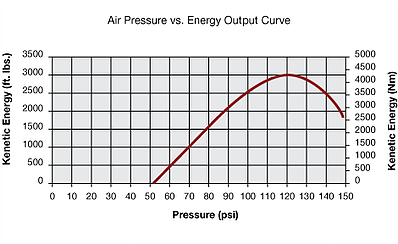

A pneumatic, semi-automatic punch designed to remove liner bolts and liners from SAG mills. Deliver 3,200 lbs. (4,340 joules or 28x times harder than a sledgehammer swing) per blow every two seconds with this simple, air powered tool. Designed for liner removal for SAG, Ball, cascade and rod mills, this tool can dramatically reduce mill downtime as well as worker injury.

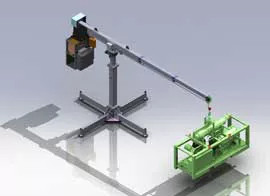

Cuts maintenance in half by using our self-contained, air powered system. Utilize a dedicated jib crane to free up overhead cranes.

Prevent injury and strain by eliminating the manual labor classically associated with bolt removal and mill relining.

Increased performance with 3,200 lbs. of pressure placed directly on bolts with only a three second reload time.

Description

The Bolt Buster has two parts: the barrel assembly and a remote control pendant. An overhead crane or optional gantry system, utilized with the pitch attitude adjustment on the unit, positions the head of the Bolt Buster impactor against the liner or liner bolt. A spring-loaded collar assists in alignment of the impactor punch to the liner bolts. To prepare the bolt buster for firing, the load button on the remote control pendant is pressed. This returns the projectile to the rear positioning for firing. The bolt buster has a safety check designed into its firing action- it requires simultaneous pressure on the arm and safety button for firing to occur. The fire button opens a valve that releases compressed air into the Bolt Buster barrel. The air propels the projectile down the barrel onto an impactor punch that strikes the liner or liner bolt. If the bolt is not removed on the first hit, the procedure is repeated until it is. Once the bolt is ejected, the Bolt Buster is positioned with the crane on the next bolt. A variety of replaceable drifts may be used to extend the impactor reach. The same drift is used

As a liner remover:

A short drift without the collar guide is used to remove liners. If the liner is not dislodged, the Bolt Buster will break it, eliminating any need for torching. Often and entire row of liners will fall with only a couple of blows.

As a bolt remover:

Using the impactor and a bolt guide collar, it takes an average of 3 or 4 blows to remove a bolt. Consistently, the Bolt Buster has punched out 12 bolts in 10 minutes.

| Dimensions | SAE | Metric |

| Overall Length | 47.7" | 1.21 m |

| Overall Height | 29.2" | .75 m |

| Overall Width | 39" | .99 m |

| Barrel Assembly Weight | 800 lbs | 354 kg |

| Air Preparation Unit Overall Length | 106" | 2.69m |

| Air Preparation Unit Height | 41.5" | 1.05 m |

| Air Preparation Unit Width | 41.0" | 1.04 m |

| Air Preparation Unit Weight1 | 1600 lbs | 727.3 kg |

| Bolt Buster Maximum Supply Air Pressure to Air Prep Unit (tank test limit) | 145 psi | 1000 kPa |

| Bolt Buster Air Pressure Range | 80-85 psi | 552-856 kPa |

| Bolt Buster Optimal Air Pressure | 80 psi | 552 kPa |

| Fastest Cycle Time | 3 seconds | 3 seconds |

| Highest Sustainable Air Flow Rate | 30 cfm | 850 liters/min |

| Impact Energy @ 120 psi | 3243.8 lb/ft | 4398 N |

| Power Requirements | 230/460/190/380 3 PH | AMPS |