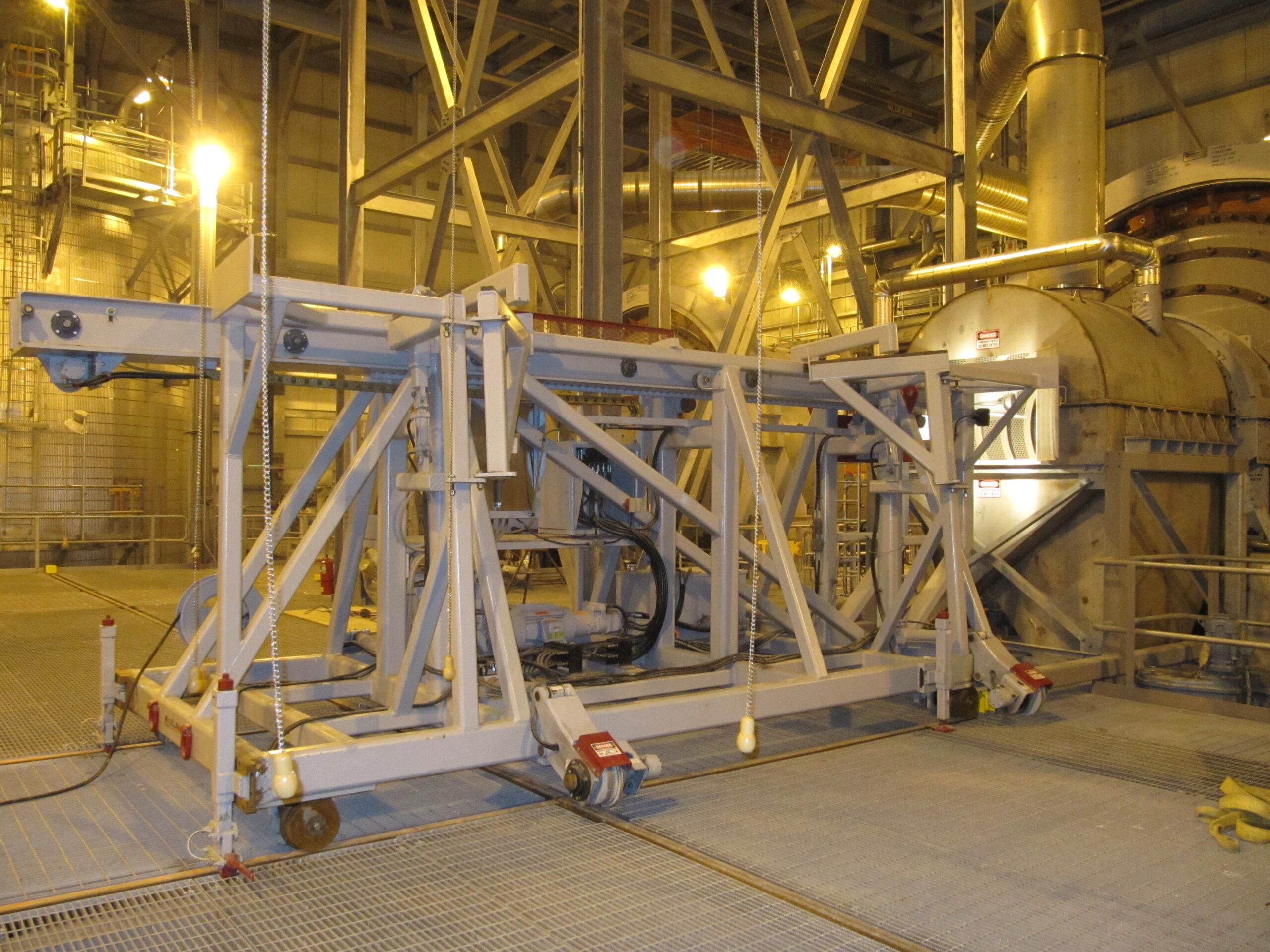

Rod Charger

Reduce rod replacing time in your rod mill with an automated solution. Our Rod Charger is designed to propel rods into mills via an extendable boom. The McLellan Rod Charger reduces time and labor during critical relining & maintenance periods. The Rod Charger is designed to be the backbone of your mill rod replenishment process. Each unit is designed to place rods through minimal trunnion openings. McLellan’s team of engineers has designed a customizable rod charging solution to fit your needs. Options include independently driven wheels or rails, rod racks for increased rod capacity, retracting beams, vertical loading, etc.

Features of Rod Charger:

- Chassis:The chassis structure houses and supports the main beam, hydraulic and electrical systems, and the rods that will be placed in the mill. The chassis structure is designed to be lifted into position with an overhead crane, then anchored in front of the mill.

- Four (4) lift eyes, for picking up chassis with an overhead crane.

- Optional polyurethane all-wheel drive system for versatile maneuvering, or fixed rail wheels for riding on existing feed chute rails.

- Corner mounted eye style, clevis style (or) rail clamp style hold downs (4).

- Operator platform in front of controls and electric panel.

- Rod rack: Rod rack holds rods in a queue to be loaded into mill. The rack is designed with the customer’s facilities in mind. Each rack is designed around a loading cycle time which ensures a constant feed into the mill, thus reducing downtime during critical maintenance periods.

- Main beam: Main beam extends into mill trunnion and delivers rods into the mill.

- The main beam receives rods from the rod rack via loading actuators.

- The beam contains a series of powered “V” rollers that drive the rods into the mill. Variable speed control allows for proper speed for propelling rods into the mill.

- Multi-size rod loading mechanism allows for loading multiple sizes,

- The beam is retractable for transport and compact storage.

- Electrical system:

- Electric panel is NEMA 4 or 4X.

- Electric panel certifications like CE / UL / CSA are available upon request.

- Incoming power supply can be 380VAC 50 Hz up to 690VAC 60 Hz, 3 phase.

- 20 HP / 15 kw Motor – 15 GPM / 57 LPM

- Trailing power cable, 100’.

- Beacon light, to alert people in the area that the Rod Charger is on the move.

- LED work lights.

- Hydraulic system:

- 60 Gal / 227 Lit Reservoir

- High efficiency, variable displacement axial piston pump, with pressure compensation.

- Thermostatically controlled oil cooling and heating.

- Machine cover for protecting against corrosive mine environment while not in use.

- Operator / maintenance manual in English and other foreign languages upon request. Manual includes comprehensive parts list and schematics.

- Start-up commissioning and training included.

- Optional top loading rod design.

- Optional remote control.

Side load rail wheeled rod charger side view.

Side load rail wheeled rod charger front iso view.

Top load rail wheeled rod charger side iso view.

Top load rail wheeled rod charger front iso view.

Side load rail wheeled rod charger with axial and transverse directions.

Side load rail wheeled rod charger with axial and transverse directions.